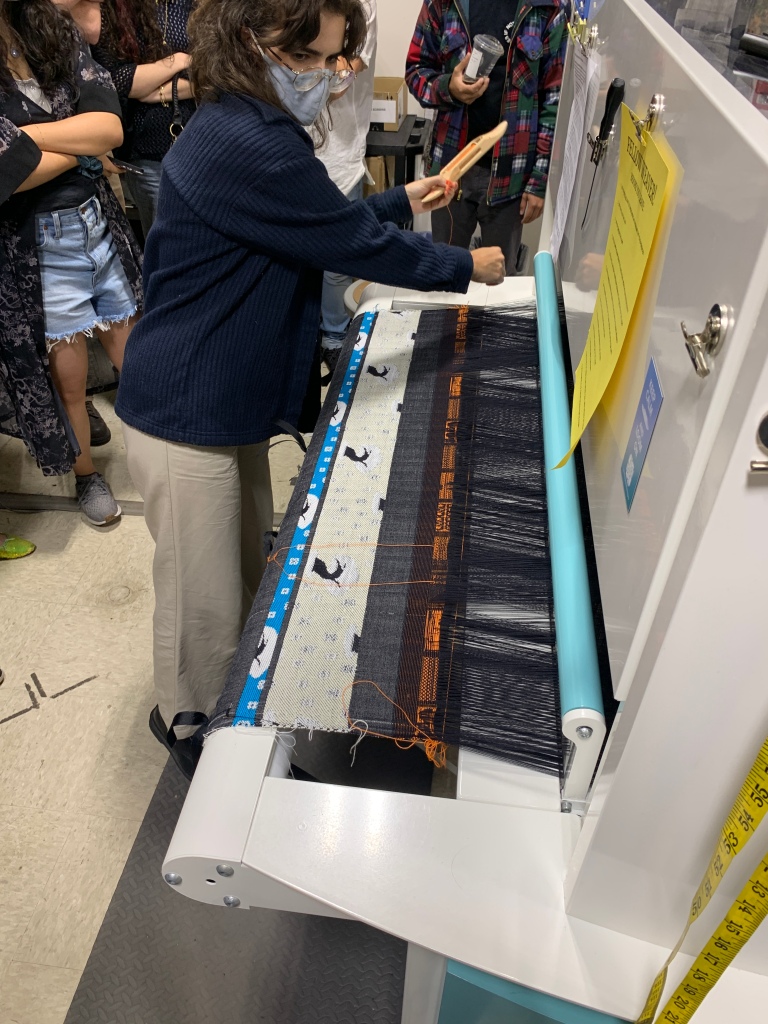

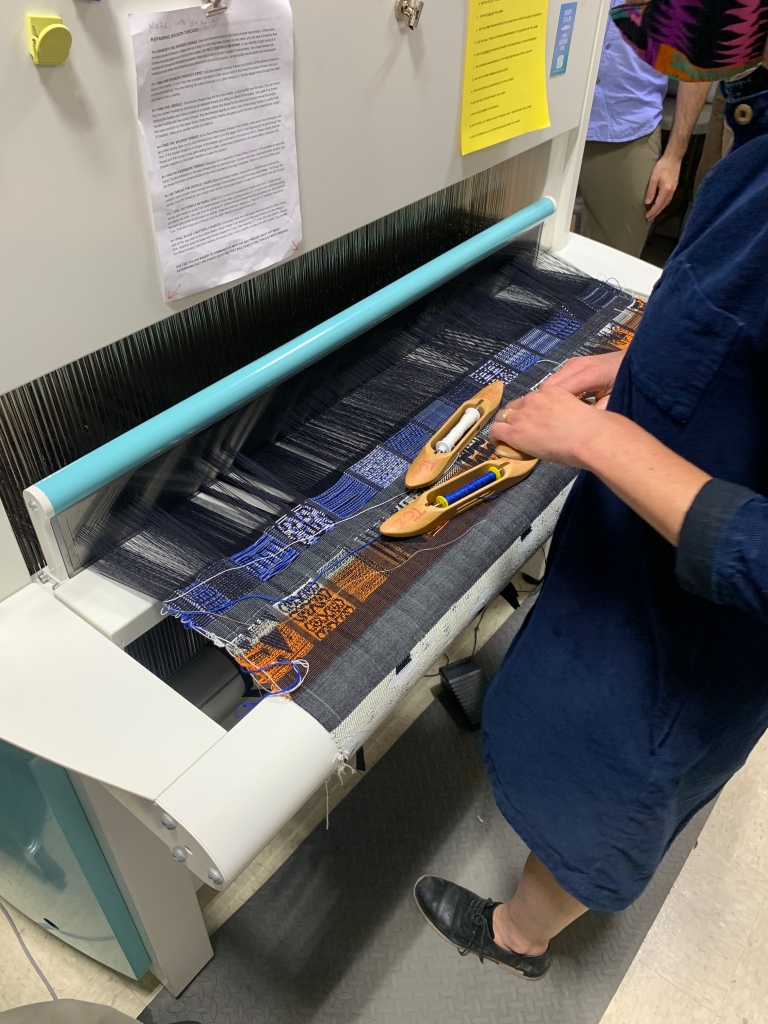

This week we had the opportunity to work with Laura Devendorf again – this time in person! Laura came and talked to us about weaving and more about her AdaCAD Software. We all uploaded our drafts, and she placed them all into one larger draft file to be woven. After the TC2 loom was set up with our drafts, we all got a chance to throw the shuttle a few times. Definitely not as easy as she made it look! Though after a few throws, a lot of people seemed to get a better sense of it and got into a rhythm, which has seemed to be my general experience with weaving. A fancier loom doesn’t change the meditative aspect of it.

It was pretty rad to see my AdaCAD file made real. From pixels to an actual fabric, all while we watched. It was a cool learning experience, seeing how the designs seen on the screen translated to actual weaving, learning what worked well and what worked less well. I could definitely imagine the benefit of just “testing” several different swatches of several different weaves to further get a sense of this, just as is the case with most new techniques. Practice makes perfect, or at least better, products.

We did our first designs with an orange thread, which feels appropriate now that I am writing this in October. Next, we began on our 2 pic drafts, using blue thread, white thread, and a conductive thread. The shuttle throwing pattern was a bot more complex, naturally. But, it yielded some cool results! I am pleased with both the drafts I made, not really knowing how closely they would translate from the screen. In my case, they seemed to be pretty close to what I had envisioned. Laura then removed the drafts from the loom and we took them back to our desks and cut them apart, realizing afterwards that cutting through the conductive threads wasn’t maybe the best idea? However, some quick troubleshooting meant that Annet could just sew the edges of our swatches with some conductive thread.

I found that mine was pretty hard to get a reading from initially. We tried rolling it up, we tried pulling it at an angle. I did see some small resistance changes when pulling it at an angle: from about 3.9 ohms when it was flat to between 6 and 8 ohms when pulled at an angle. I saw the most significant changes when it went from flat, again about 3-4 ohms, and when I crumpled it into a ball: about 17 ohms.

Laura also asked us for any suggestions we had for her software, which was pretty cool to hear people’s ideas and even cooler to have the actual developer there, who was receptive and actively listening to any suggestions. Overall a really pleasant introduction/further elaboration on the intersection of weaving, computing, and electricity.

I thought it was very festive that we wove in black and orange too! How appropriate haha. I’m impressed that your drafts and your weaves are so similar! Well done.

LikeLike